Rice Process

Sake brewing begins with polishing brown rice. Getting good steamed rice is a first step toward brewing good sake.

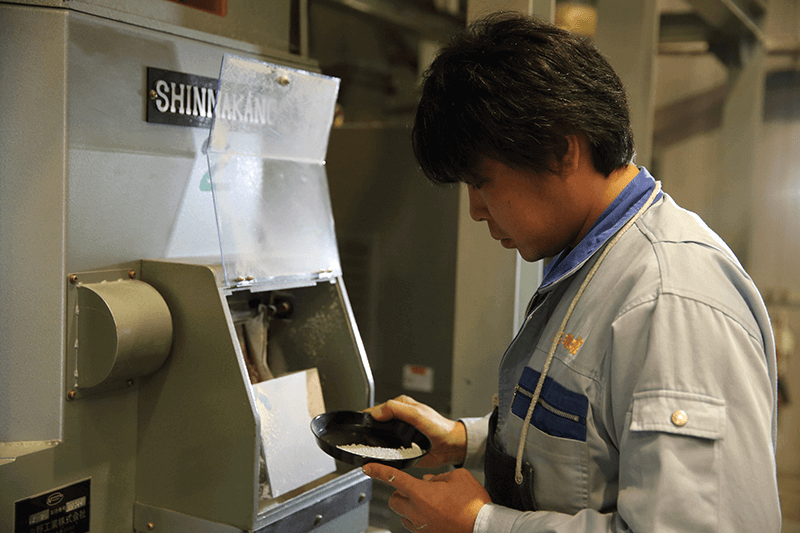

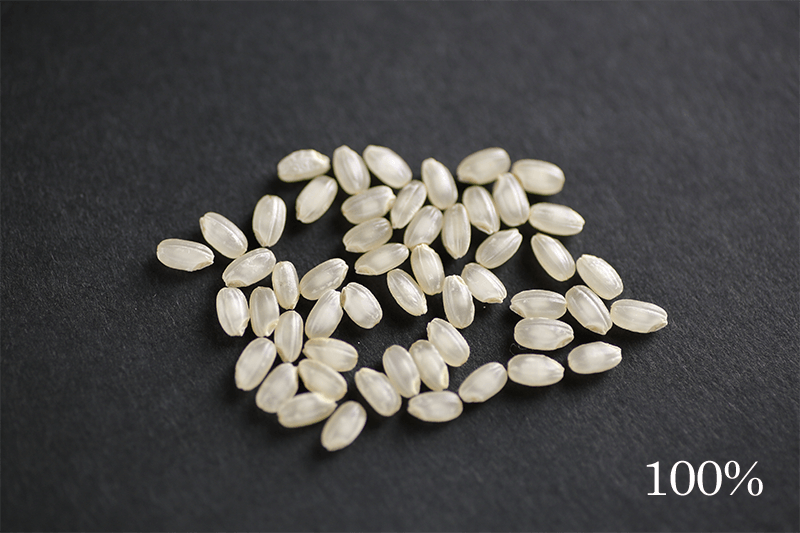

Polishing Rice

The outer part of a grain has much proteins, lipids and minerals, which cause negative aromas and flavors. Thus, the outer part must be milled away to brew clear tasted sake. Usually, this process is done by contractors but we polish rice with our own polishing machines. A polishing ratio shows the degree to which the rice has been polished. Our average polishing ratio is 50%.

Washing Rice

Rice is washed to remove the rice bran and soaked to attain a certain water content deemed optimum for steaming that particular rice. The soaking time is controlled strictly on the second time scale. Although conditions, such as air temperatures, water temperatures and qualities of rice, are different every day, we find the best solution with a huge number of recorded data and skilled techniques.

Steaming Rice

Rice is steamed with Koshiki, which is a traditional steamer. Ideal steamed rice should be firm on the outside and soft on the inside. The steamed rice is carried to Koji-muro, which is a Koji making room, and fermentation tanks.