Management process

It is our responsibility to deliver sake in its best condition. We are doing various efforts for that.

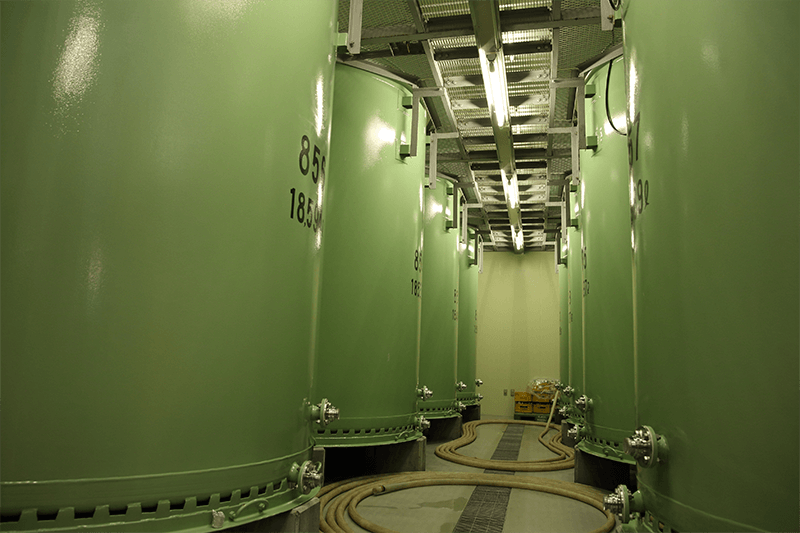

Chozo (Storage)

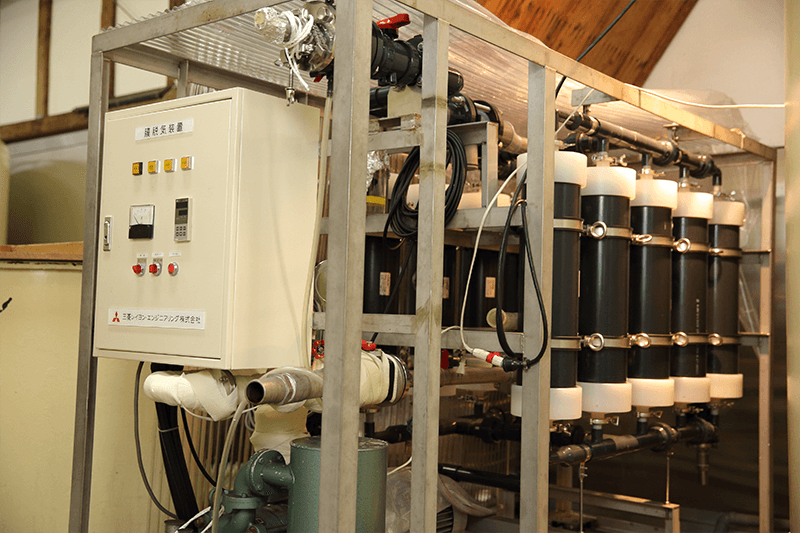

Dewazakura has storage facilities capable of storing all its produces (140,000 kiloliters) at minus 5 degrees Celsius. We are also the first sake brewery in Japan that has oxygen reduction equipment. We remove oxygen from sake before letting it mature in a storehouse, where the temperature is maintained at minus 5 degrees Celsius. This process allows us to avoid oxidation-induced degradation and ship high-quality sake year round.

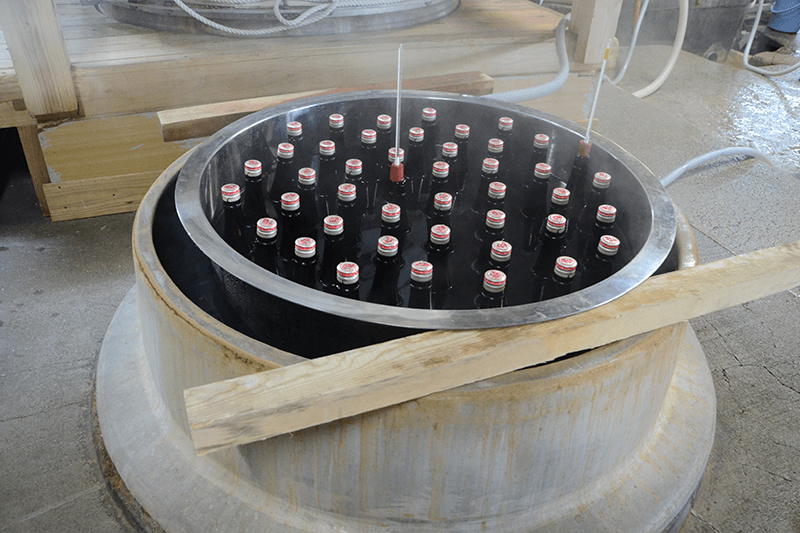

Pasteurization

We employ special techniques to prevent Ginjo sake from losing its fruity scent in a pasteurization process. We bottle unpasteurized sake and seal the bottles with a crown cap. We then put each bottle in hot water to bring it to a temperature of 65 degrees Celsius. The sealed bottles prevent the scent from escaping.

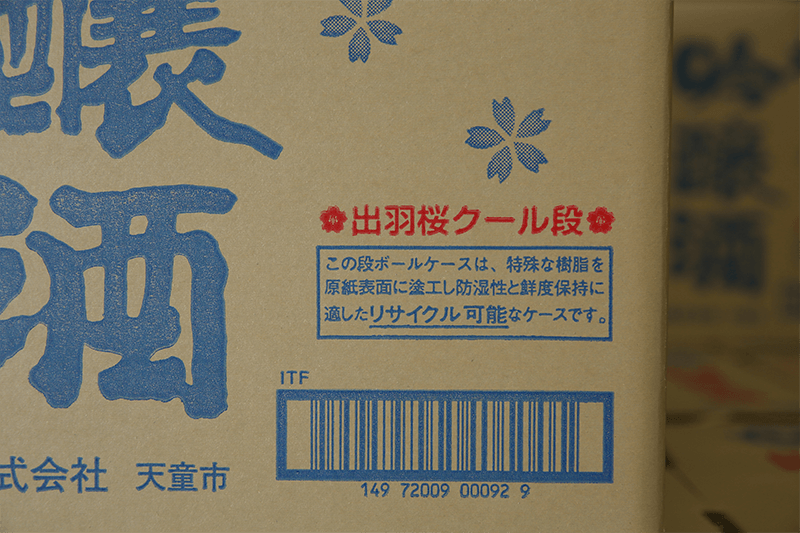

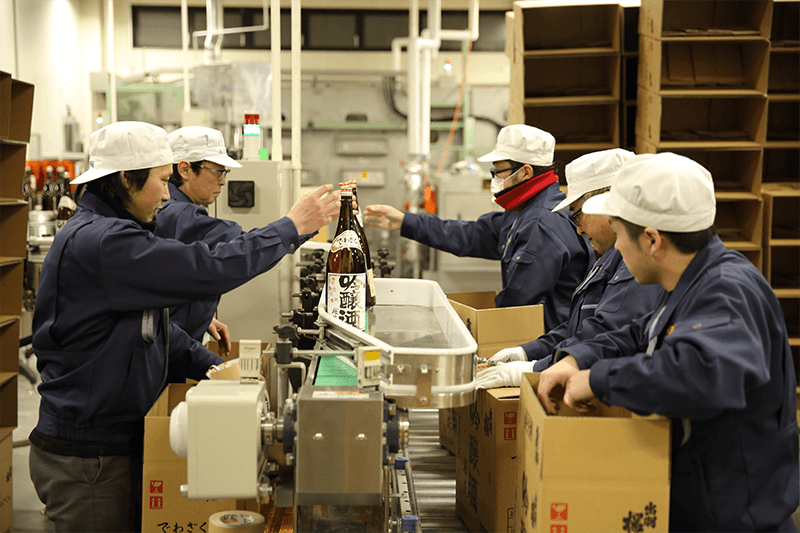

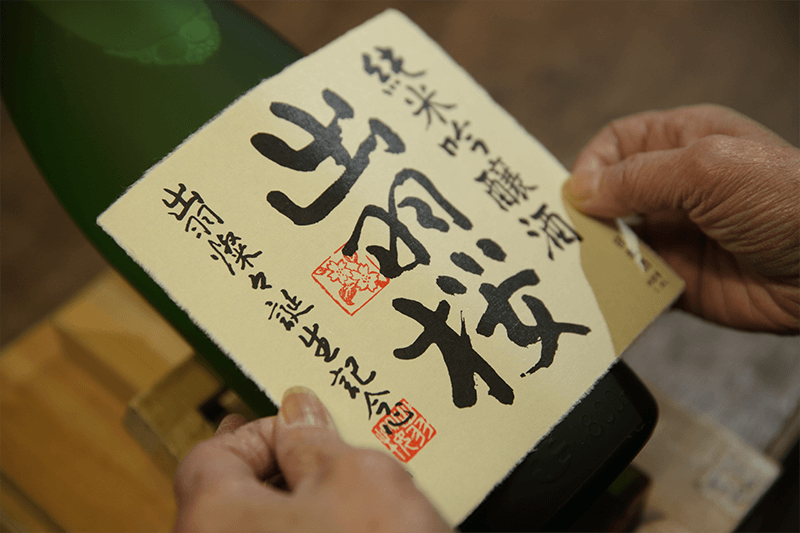

Bottling / Shipping

We carefully bottle and manage again in the refrigerators not to deteriorate before shipping. After shipping, we also continue our efforts to deliver our products to consumers by cooperating with our partners in all over the world.